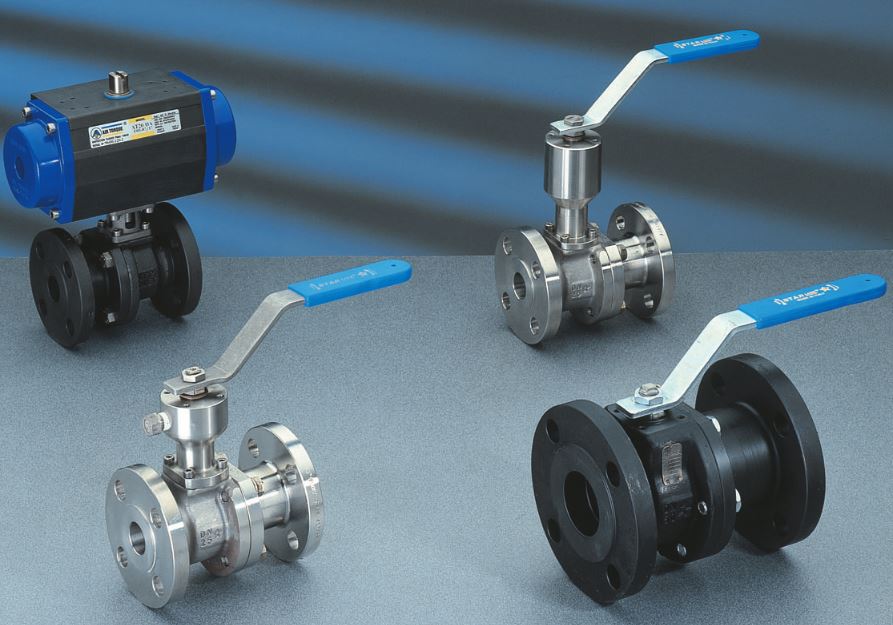

Ball Star

Starline Ball Valves – Precision that matters. Our forged steel ball valves guarantee reliability and durability. With a wide range of sizes and designs, we offer customized solutions for the highest demands in the oil and gas industry. Trust Starline for innovative and robust valve solutions that maximize your operational safety and efficiency.

Blow-out-proof design

As standard, the ball valves come with a blow-out-proof stem to prevent the operating personnel against potential injury in case the valve stem is ejected uncontrollably.

Anti-static design

STARLINE ball valves are reliably protected again electrostatic discharging by a small spring attached to the bottom end of the stem. This prevents explosive atmospheres from being ignited.

Exclusive seat design

The ball valves are designed to allow for easy replacement of the seat. This applies to the standard version as well as the encapsulated version, which provides better resistance to high pressures and temperatures while using the same seat materials.

STARLINE ball valves with SAMSON actuators

Valve accessories

-

Positioners

SAMSON offers a wide variety of positioners. Positioners ensure a predetermined assignment of the valve position to the input signal. They compare the control signal issued by pneumatic or electric automation equipment to the position or opening angle of the control valve and supply a corresponding output signal pressure. Smart positioners come with the integrated EXPERTplus valve diagnostics, which include special functions for on/off service in the TROVIS SAFE version.

-

Limit switches

Limit switches are suitable for automation of on/off applications and issue an electric binary signal when the valve travel exceeds or falls below an adjusted limit. The signal can be used, for example for switching control signals, issuing visual and audible alarms or for connection to central control or alarm systems. SAMSON's product range includes limit switches with inductive, software, electric or pneumatic limit contacts.

-

Solenoid valves

Solenoid valves serve as switching elements for the opening and closing of the valve assembly or act as safety control circuits for connected control valves. They are the interfaces between the electric control level and the pneumatic actuator. SAMSON solenoid valves are characterized by their high level of operational reliability and minimal power consumption. The Type 3969 Solenoid Valve additionally operates without consuming any air, which makes it a particularly energy-efficient solution.

-

Pneumatic lock-up valves

Lock-up valves are used to shut off the signal pressure line of pneumatic actuators. They shut off the line either when the air supply falls below an adjusted limit or in case of complete air supply failure. This causes the actuator to fail in place. The SAMSON Type 3709 Pneumatic Lock-up Valve is available in various versions for different types of attachment and flow coefficients. All versions have an easily accessible adjustment screw for fine tuning the switching point.

-

Supply pressure regulators

Supply pressure regulators are used to provide pneumatic measuring and control equipment with a constant supply pressure. They reduce and control the pressure of a compressed air network to the pressure adjusted at the set point adjuster. SAMSON's Type 4708 Supply Pressure Regulator can be used in a wide variety of applications. The regulator is quick and easy to adjust at the adjustment screw. Low-temperature versions for use down to –50 °C are available for some device versions.

-

Volume boosters

Volume boosters are used together with positioners to increase the positioning speeds of pneumatic actuators. They influence the process to vent or supply the actuator, which causes the control valve to open or close more quickly. SAMSON's Type 3755 Pneumatic Volume Booster features a linear characteristic and an ideal boost ratio. It can be quick and easily adapted to the specific application at the bypass screw which can be lead-sealed.

-

Quick exhaust valves

Quick exhaust valves are used to reduce the time required for venting pneumatic actuators. The Type 3711 Quick Exhaust Valve features a particularly compact design and a high flow coefficient. The integrated restriction allows the response of the valve to be adjusted to meet the requirements of the application. If required, the exhaust air can be discharged through a pipe and, for example fed back for purging of the actuator spring chamber.

These industries work with our solutions