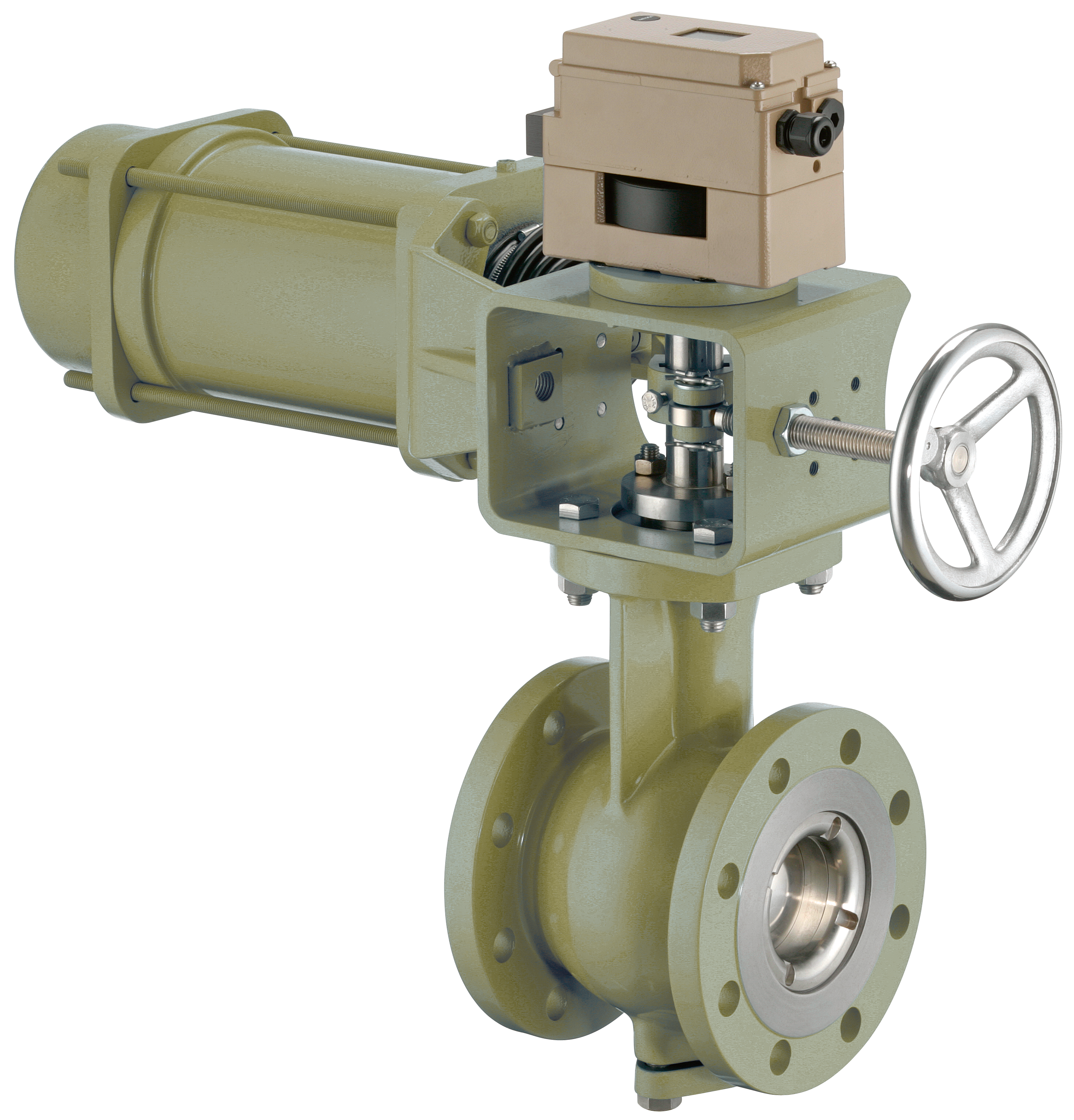

The Rotator

The Maxifluss Rotary Plug Valves have a double-eccentric plug, which moves away from the seat without any friction as soon as it opens. The valves are designed with an optimized flow contour to permit high flow rates. The high KVS coefficient and control ratio of 200:1 make the valves suitable for a wide range of applications. Thanks to the double-eccentric design of the rotary plug, the full cross-section of flow is released leaving the flow path unobstructed.

Flexible flow control

Various seat features are available for rotary plug valves, allowing the KVS coefficients to be adapted to suit the process conditions. As a result, the valves can be configured to meet specific process requirements and to make best possible use of the control range.

Control over a wide load range

The rangeability of the double-eccentric rotary plug valves is between 100:1 and 200:1. As the plug moves closer to the seat to close the valve, the flow rate is changed gradually until the plug contacts the seat. This means, in theory, the valves can control within a range including a zero flow rate.

Design advantage

Much smaller actuators can be used since the plug moves crossways to the flow path. As a result, the plug is only fully exposed to the flow forces in the closed position.

Blow-out protection

ACHEMA 2022

Control valves from a single source

-

AIR TORQUE S.p.A.

The world leader in pneumatic rotary actuators manufactures actuators for all kinds of rotary or quarter-turn valves. Technical highlights provided by AIR TORQUE actuators include external travel stop adjustment and the involute gearing of the rack and pinion, which converts the linear motion into a smooth rotary movement.

-

CERA SYSTEM Verschleißschutz GmbH

High-performance ceramic materials provide solutions wherever standard valves reach their limits in resistance to wear, corrosion and high temperatures. CERA SYSTEM specializes in ball and sliding disk valves as well as pipe components with ceramic linings. High-precision components made to meet specific customer requirements round off the product range.

-

LEUSCH GmbH Industriearmaturen

High-performance valves up to three meters in pipe diameter are the specialty of SAMSON LEUSCH. Process and control butterfly valves, ball valves and segmented ball valves with soft or metal seals can be used in both extremely high and extremely low temperatures and at high pressures: from –196 to +1000 °C, in pressure ratings up to PN 420/Class 2500.

-

Pfeiffer Chemie-Armaturenbau GmbH

The high-quality control, butterfly and ball valves with homogenous PTFE and PFA linings can be used in a wide variety of applications. The product portfolio also includes metal butterfly and ball valves, turnkey pigging systems and their components as well as sampling systems.

-

RINGO VÁLVULAS S.L.

The valve specialist is well known for its large valves with high pressure ratings specifically designed for the oil and gas sector and power stations. The company’s wide product range includes ball valves, globe control valves, gate, globe and check valves, choke valves, axial flow valves as well as special valves, such as double block-and-bleed or subsea valves.

-

SAMSON AKTIENGESELLSCHAFT

Since it was founded 115 years ago, SAMSON develops and manufactures control equipment for industrial processes. From rugged self-operated regulators to highly specialized process control valves, SAMSON manufactures devices in all common sizes, in standard materials and exotic alloys, equipped with different actuators, tailor made for the specific demands of each application. In addition, SAMSON's product portfolio includes turnkey control systems.

-

SED Flow Control GmbH

SED specializes in the development, manufacture and distribution of diaphragm valves, seat valves and variable area flow meters. In addition, SED offers a wide range of mechanical and electric accessories for monitoring and control that is perfectly tailored to the valves. Valve bodies and actuator components are made of high-quality metals and plastic materials.

-

STARLINE S.p.A.

Forged steel ball valves in sizes NPS ¼ to 36 and Class 150 to 2500 as well as in API 6A pressure ratings are used in special applications, such as upstream, cryogenic and high-temperature service. Thanks to superior quality, STARLINE is a top supplier to all major oil and gas companies as well as EPC contractors.

-

VETEC Ventiltechnik GmbH

VETEC's Maxifluss valves combine the advantages of conventional control valves, butterfly valves and ball valves. Their universal design allows them to be used in standard and critical applications. Thanks to the eccentric design of the rotary plug, it only comes into contact with the valve seat when the valve is completely closed. This means that the valves can control with a high rangeability.

These industries work with our solutions