The Doorkeeper

Hydrogen approved

1. Applicable for hydrogen > 550bar

2. SAMSON Hydrogen Valve Know How

Chemical and pharmaceutical industry approved

Green steam is produced by electric generators powered by green electricity. Using off-grid renewable energy to power your steam generators is the perfect way to save money.

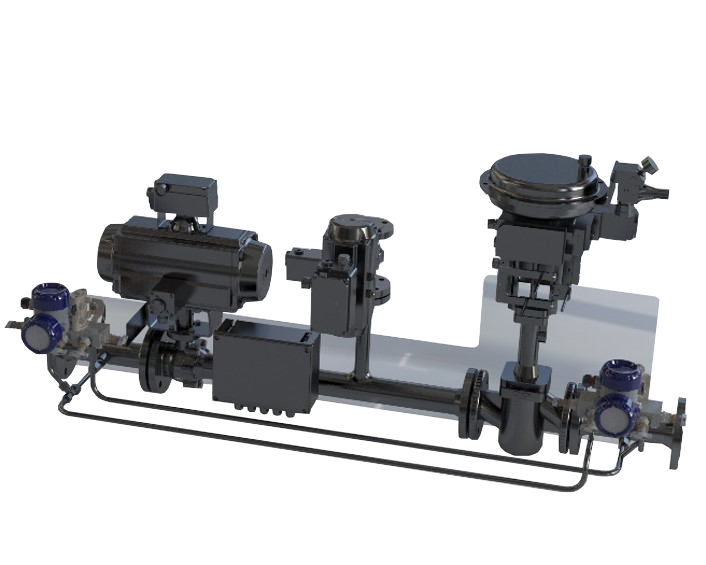

Ready-to-use units

Creation of a SIL circuit calculation and documentation of the SIL characteristic values of the combination (skid) in a SAMSON manufacturer's declaration< br/> Valves, safety control circuit and instrumentation from a single source

Here's a deep dive

ACHEMA 2022

Modular systems

-

Product range

We develop and manufacture smart system solutions using components made by SAMSON for a wide variety of applications in steam and condensate systems, media conditioning and production engineering.

-

Consulting

We support you in defining and implementing the safety requirements for your application. Our consulting services also include an extensive safety analysis to determine the function and suitable components to be used.

-

Planning and project management

We help you plan and manage your project. Take advantage of our engineers' know-how right from the start for selecting sensors, control valves and PCs, sizing pipelines, planning the control operations, calculating the SIL loop and drafting the documentation for your application.

-

Installation and start-up

For optimal operation, it is important that all components within a modular system are configured, wired and mounted correctly. We provide checklists to support you during installation and start-up. Alternatively, you can entrust us with all the start-up activities, including function testing of the entire system.

-

Maintenance and servicing

SAMSON provides you with extensive documentation for maintenance, troubleshooting and proof testing. Our global network of over 200 representatives provides hands-on assistance on site. No matter where you are located, you can rely on our experts to support you during maintenance and service work. They are also at hand to help you modify or upgrade your plant.

These industries work with our solutions