Energy Transition Challenges

The energy transition is one of the biggest challenges of our time. The ambition to leave behind oil, gas and coal calls for different procedures and – in some applications – also different equipment than what is used in traditional energy and heat generation processes. SAMSON manufactures valves and modules ready to take on the changing requirements in a changing world.

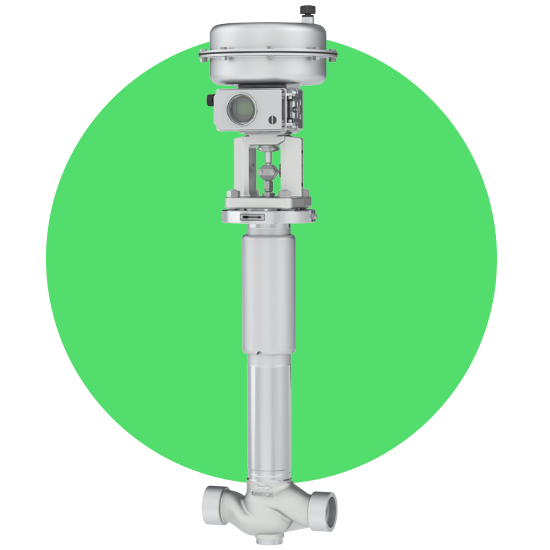

Daddy Cool

Our cryogenic valves for liquid hydrogen can master the challenges posed by the combination of cryogenic medium temperatures and hydrogen as the process medium; they minimize the heat intake from the atmosphere to the inside of the valves. They withstand the hydrogen, which has a tendency to permeate their material structure and cause stress corrosion cracking. All wetted parts retain their strength and proper functioning over a very long period of time.

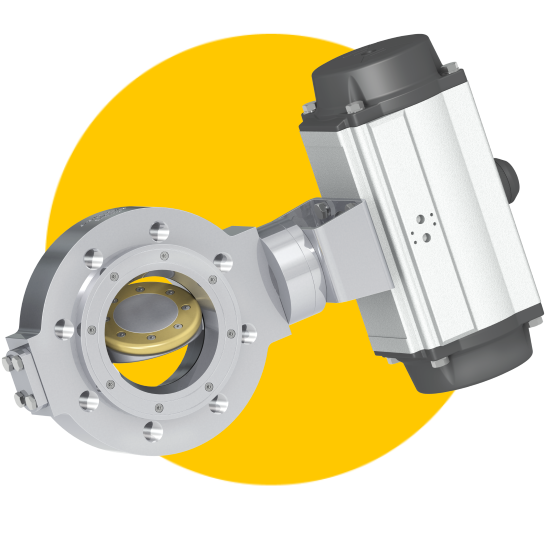

The Unbreakable

The pressure swing adsorption process can produce hydrogen of up to 99.99 % purity. The process requires extremely rugged valves that can operate reliably even when faced with fluctuating conditions, such as a high number of switching cycles, long idle times and frequent load changes. The PSA butterfly valves by SAMSON PFEIFFER are specially engineered to tackle the challenges posed by pressure swing adsorption and are designed to be extremely resistant to wear.

The Steam Machine

Steam is required in many industrial processes. Steam generators by SAMSON allow steam to be generated directly on site where it is needed without having to use oil or gas. There are many technical advantages in favor of electric steam generators. What is more, the generators are climate neutral when powered by steam generated from green electricity. Using off-grid renewable energy to power your steam generators is the perfect way to save money.

.jpeg)

.png)